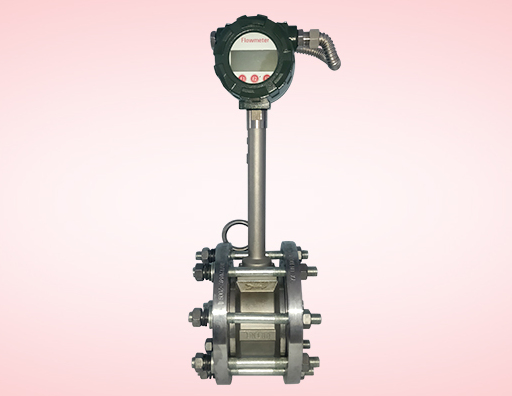

VORTEX FLOW METER

The measuring principle is based on the Karman vortex street. The measuring tube contains a bluff body at which vortex shedding occurs and which is detected by a sensor unit located behind. The frequency f of the vortex shedding is proportional to the flow velocity v. The nondimensional Southall number S describes the relationship between vortex frequency f, width d of the bluff body and the average flow velocity v:

f=SV/d. The vortex frequency is recorded at the flow sensor and evaluated at the signal converter.

Vortex flowmeters are used to measure the flow of gases, vapours and liquids at completely

1.Measurement of saturated steam and superheated steam

2.Steam boiler monitoring

3.Heat metering of steam and hot water

4.Wide range of applications, gas, liquid, steam flow can be measured

5.Measurement of consumption in compressed air systems

6.Industrial Gases i.e. Air, Oxygen, Nitrogen, Coal Gas, Natural gas. etc.

7.Industrial Liquids i.e. Water, Oil, Food liquid, Chemicals etc.

SPECIFICATION

| Medium | Steam, Compressed Air, Oxygen, Nitrogen,Natual Gas, Gasoline, Light Oils, Heavy Oils, Food Oils, Solvents, Lubrication Oils, Chemicals, Pharma Chemicals, Clear Hot Water etc. |

|---|---|

| Size | DN25~DN300mm |

| Accuracy | ±0.5% |

| Repeatability | ±0.1% of Span |

| Medium temperature | -40’C to 350’C |

| Medium pressure | up to 60 Bar |

| Body Material | SS304,SS316 |

| Compensation | Pressure & Temperature Compensation |

| Enclosure Material | Aluminium |

| Power supply | 24VDC,lithium battery |

| Signal output | 4~20mA, Pulse-NPN and Relay |

| Communication Protocol | RS485,GSM/GPRS,HART,LORA/NB-IOT |

| Display | LCD Display, Flow rate, Totalizer, Pressure Temperature |

| Explosion-proof | Flame Proof (FLP) |

| Protection proof | IP65,IP67& IP68 |

| Flow Transmitter | Integral, Remote |

| Work environment | Ambient temperature:-20~+60’C,Ambient humidity:5%~85% |

| End Connection | Flange-end and Wafer Connection |