BTU METER

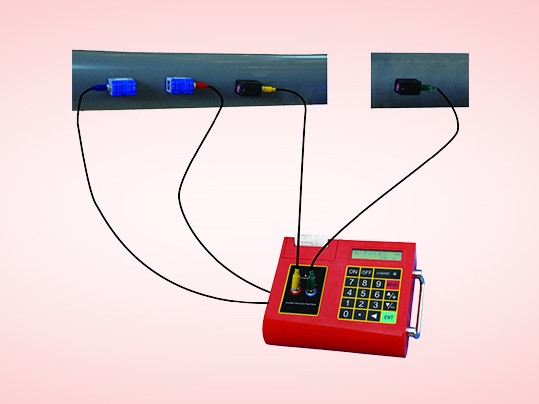

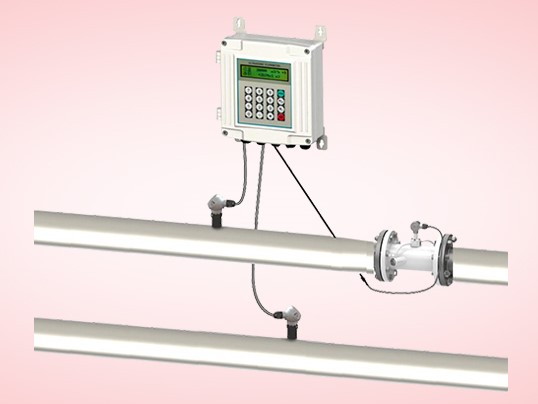

BTU Measurement System is used to measure individual energy consumption in any liquid heating/cooling systems. This system is also used to measure the performance of the energy -saving system or the loss of efficiency which is directly tied to the loss of revenue. BTU Meter is supplied complete with flowmeter and temperature probes. The system real-time detect the temperature of supply and return pipe. It also monitors the instantaneous flow rate according to the Heat Exchange of Thermodynamics principle. The BTU meter automatically integrates energy consumption and transfers it to the computer. The consumption volume can be checked by a tenant or operator with no worries. It provides real-time information such as instantaneous temperature, flow rate, energy consumption, and others. The BTU Meter provides highly accurate thermal energy measurement in chilled water, hot water and condenser water systems based on signal inputs from two matched temperature sensors and any of Magnetic or Ultrasonic flow meters. The basic model provides local indication of energy, flow, and temperature data through an alphanumeric display. An isolated solid state dry contact is provided for energy total. Optional analogue outputs and network communications are also available. BTU meter calculates energy consumption by flow rate and temperature difference.

SPECIFICATION

| Medium | Chilled Water, Hot Water and Condenser water system |

|---|---|

| Diameter | DN15~DN6000mm |

| Accuracy | ±0.5% |

| Repeatability | ±0.2% of Span |

| Medium temperature | <180B |

| Medium pressure (Kg/Cm2) | 10,16,25,40 |

| Flow rate | 0.3~10m/s |

| Display | LCD Display, Flow Rate,Totalizer,heat flow rate, heat totalizer |

| Temperature Inputs | Pt 100/Pt1000 |

| Flow rate Input l | 4-20mA |

| Flow sensor Input Type | Ultrasonic, Electromagnetic, Turbine etc |

| Mounting | Portable, Wall Mount |

| Energy Function | Heat/Cool |

| Power supply | 230VAC/24VDC/Battery Powered |

| Signal output | 4~20mA, Pulse and Relay |

| Communication | RS485,GSM/GPRS,HART |

| Electronic Enclosurer | Aluminium, ABS Plastic, MS |

| Protection proof | IP65 (compact type); IP67,IP68(suitable for remote type) |

| Transmitter | Integral, Remote |

| Work environment | Ambient temperature-20~+60’C Ambient humidity:5%~90% |

| End Connection | Flange-end, Wafer, Tri-Clover ,Clamp on,Insertion |